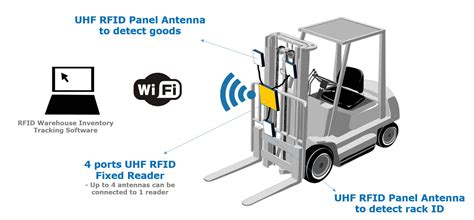

retail product tracking in warehouse using rfid With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously. Tap Tag is a US based company out of New York. Here, our customers come .

0 · rfid warehouse tracking system

1 · rfid tracking systems for inventory

2 · rfid tracking of inventory

3 · rfid labels for inventory tracking

4 · rfid inventory tracker

5 · rfid for warehouse inventory

6 · rfid asset tracking system

7 · active rfid tracking system

NFC, or near-field communication, is a short-range wireless technology that allows your phone to act as a transit pass or credit card, quickly transfer data, or instantly pair with Bluetooth .In this article, we’ll explore each NFC forum tag type and provide examples of NFC cards that belong to these types. NFC Forum Tag Type 1. NFC Forum Tag Type 1 is based on the ISO14443-A standard and is known for its simplicity and flexibility. It’s rewritable and can be .

With an RFID warehouse management tracking system, items can be scanned and catalogued . RFID inventory tracking allows you to manage inventory without having to scan .

With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

RFID inventory tracking allows you to manage inventory without having to scan every single item. You can even use RFID tracking in-store to track purchases. How does RFID work in retail environments? RFID’s most common application within retail is tracking individual items or pieces of stock. Individual RFID tags are applied to products, and the products are then scanned, either manually by a staff member, by a fixed reader, or by a combination of both.

Optimize operations with our reliable RFID warehouse tracking system. Take control of retail product tracking using RFID, robust hardware, and innovative software for enhanced efficiency. Real-time tracking of products with RFID technology enhances inventory accuracy by up to 27%. RFID systems significantly speed up processing times by reading multiple tags simultaneously. Implementing RFID can reduce labor costs by up to 30% and improve inventory accuracy rates to 99%.

rfid warehouse tracking system

By implementing item-level RFID, retailers can significantly improve their ability to track and manage inventory throughout the supply chain. RFID enables near-real-time data capture, providing retailers with precise visibility into the location and movement of their products.

RFID asset tracking offers a solution by creating an automated record trail that collects information to adhere to guidelines. By using RFID tags on items or packages, businesses can conveniently keep track of expiry dates, as .Streamline your warehouse operations with real-time inventory visibility using the latest tracking technologies including RFID, BLE or UWB.

Inventory management: RFID allows for precise, real-time inventory tracking. Retailers can count and locate products quickly and effectively, eliminate stockouts and overstock, optimize inventory levels, and increase overall supply chain visibility.

How is RFID used to track inventory? Retailers use RFID to track inventory by tagging items, bundles, or bins. These tags emit signals to RFID readers. These readers receive information without needing a direct barcode scan, tracking all inventory within range.

rfid tracking systems for inventory

With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

RFID inventory tracking allows you to manage inventory without having to scan every single item. You can even use RFID tracking in-store to track purchases. How does RFID work in retail environments? RFID’s most common application within retail is tracking individual items or pieces of stock. Individual RFID tags are applied to products, and the products are then scanned, either manually by a staff member, by a fixed reader, or by a combination of both.

Optimize operations with our reliable RFID warehouse tracking system. Take control of retail product tracking using RFID, robust hardware, and innovative software for enhanced efficiency. Real-time tracking of products with RFID technology enhances inventory accuracy by up to 27%. RFID systems significantly speed up processing times by reading multiple tags simultaneously. Implementing RFID can reduce labor costs by up to 30% and improve inventory accuracy rates to 99%.

By implementing item-level RFID, retailers can significantly improve their ability to track and manage inventory throughout the supply chain. RFID enables near-real-time data capture, providing retailers with precise visibility into the location and movement of their products. RFID asset tracking offers a solution by creating an automated record trail that collects information to adhere to guidelines. By using RFID tags on items or packages, businesses can conveniently keep track of expiry dates, as .

Streamline your warehouse operations with real-time inventory visibility using the latest tracking technologies including RFID, BLE or UWB.Inventory management: RFID allows for precise, real-time inventory tracking. Retailers can count and locate products quickly and effectively, eliminate stockouts and overstock, optimize inventory levels, and increase overall supply chain visibility.

rfid tracking of inventory

3m rfid tag dispenser

3m rfid tag placement

BBB has tips on what NFCs can do and how to stay safe when using them. What exactly is NFC? . especially when technology is linked to your credit card or bank account. So how risky is NFC .

retail product tracking in warehouse using rfid|rfid tracking of inventory