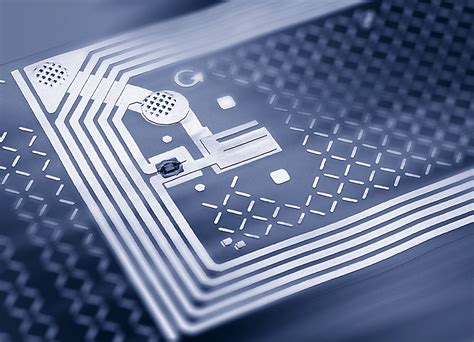

rfid card manufacturing process Discover how RFID tags are manufactured. From antenna creation to chip installation and quality testing, learn how RFID technology is crafted and what innovations shape its future. Explore key challenges and advancements in RFID tag production. How to Watch Auburn vs. New Mexico State. When: Saturday, November 18, 2023 at 4:00 PM ET. Location: Jordan-Hare Stadium in Auburn, Alabama. TV: Watch on SEC Network.

0 · what is an rfid operator

1 · rfid tracking systems for manufacturing

2 · rfid tags for manufacturing

3 · rfid systems for manufacturing

4 · rfid solutions for manufacturing

5 · rfid production tracking system

6 · rfid manufacturing inventory management

7 · rfid manufacturing companies

Here’s how: Open the Settings app. Tap on “Wallet & Apple Pay.”. You’ll see a list of your cards. To turn off a card, just tap on it and then toggle off the “Express Transit Card” .

This comprehensive guide will provide you with everything you need to know about RFID in manufacturing, from getting started to best practices and more. By the end of this .

what is rfid tag in car malaysia

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work? This comprehensive guide will provide you with everything you need to know about RFID in manufacturing, from getting started to best practices and more. By the end of this article, you’ll be well-equipped to harness the full potential of RFID technology in .RFID technology facilitates inventory management, process automation, and quality control in manufacturing. Manufacturers use RFID tags to track raw materials, work-in-progress items, and finished goods, enabling real-time monitoring of production processes, improving inventory accuracy, and reducing operational inefficiencies.

what is an rfid operator

Discover how RFID tags are manufactured. From antenna creation to chip installation and quality testing, learn how RFID technology is crafted and what innovations shape its future. Explore key challenges and advancements in RFID tag production. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.

The introduction of RFID technology has brought unprecedented transformation to manufacturing. Through automated data collection and processing, manufacturing has leapt from traditional manual operations to intelligent management. We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly.RFID application in manufacturing not only improves efficiency and management but also brings many unexpected benefits. By realizing automatic data acquisition and real-time tracking, RFID technology optimizes the operation process of the manufacturing industry in many aspects. In manufacturing, RFID is often used for complete traceability of inventory, parts, and components, so they can be tracked automatically from the receiving dock all the way through production processes and finished goods.

rfid tracking systems for manufacturing

rfid tags for manufacturing

If you’re wondering how widespread RFID technology is, just about every industry uses it. Healthcare, logistics, manufacturing, agriculture and transportation are just a few examples. RFID tags and readers communicate accurate amounts and locations of .

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?

This comprehensive guide will provide you with everything you need to know about RFID in manufacturing, from getting started to best practices and more. By the end of this article, you’ll be well-equipped to harness the full potential of RFID technology in .

RFID technology facilitates inventory management, process automation, and quality control in manufacturing. Manufacturers use RFID tags to track raw materials, work-in-progress items, and finished goods, enabling real-time monitoring of production processes, improving inventory accuracy, and reducing operational inefficiencies.Discover how RFID tags are manufactured. From antenna creation to chip installation and quality testing, learn how RFID technology is crafted and what innovations shape its future. Explore key challenges and advancements in RFID tag production. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.The introduction of RFID technology has brought unprecedented transformation to manufacturing. Through automated data collection and processing, manufacturing has leapt from traditional manual operations to intelligent management.

We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly.RFID application in manufacturing not only improves efficiency and management but also brings many unexpected benefits. By realizing automatic data acquisition and real-time tracking, RFID technology optimizes the operation process of the manufacturing industry in many aspects.

In manufacturing, RFID is often used for complete traceability of inventory, parts, and components, so they can be tracked automatically from the receiving dock all the way through production processes and finished goods.

rfid systems for manufacturing

rfid solutions for manufacturing

Turn on NFC in your iPhone 15 settings. Check that the app or device is NFC-compatible. Hold your iPhone close to the NFC tag or reader. Wait for a notification on your .

rfid card manufacturing process|rfid systems for manufacturing