rfid chips for machine tools With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.

Amiibo cards are ridiculously simple, and only need a few things: –Tagmo for an Android with NFC functionality, or other methods without .

0 · zoller rfid chip

1 · rfid machine tools

2 · rfid identification system

3 · rfid identification

4 · balluff rfid

$12.00

The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders. Tools are measured at the presetter where tool data is written to the RFID tag.

TMAC tool monitoring system measures tool wear and detects breakage by monitoring true .

zoller rfid chip

rfid machine tools

The RFID chip is written on the presetting and measuring machine and automatically read by the tool machine. Writable data are: Geometry data (actual tool data) Type number. IKZ. .The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders. Tools are measured at the presetter where tool data is written to the RFID tag.The RFID chip is written on the presetting and measuring machine and automatically read by the tool machine. Writable data are: Geometry data (actual tool data) Type number. IKZ. Subboard observation. Tool life. and more. Automatic read/write station.With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.

RFID data can be used for asset management and predictive maintenance. The tag can store process-related data such as the tool operating time. Targeted regrinding or replacement of individual tools can be carried out as required.Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management. All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available. By automating tool loading and data transfer, ToolConnect drastically reduces machine tool setup time, empowering operators to focus on production rather than manual tasks. Moreover, ToolConnect ensures accuracy and reliability, ultimately maximizing chip-cutting time and minimizing disruptions.With ZOLLER, you can already securely transfer tool data to your CNC machine(s) no matter the manufacturer: Via RFID chip, post-processor (DNC system, Distributed Numerical Control), or even through higher level manufacturing control systems.

Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.In CNC applications, RFID provides a solution to ensure the right tooling is in place before a process is allowed to begin.

The ToolConnect RFID System automatically transfers tool presetter measurement data directly to and from the CNC control via RFID tags embedded in tool holders. Tools are measured at the presetter where tool data is written to the RFID tag.The RFID chip is written on the presetting and measuring machine and automatically read by the tool machine. Writable data are: Geometry data (actual tool data) Type number. IKZ. Subboard observation. Tool life. and more. Automatic read/write station.With Balluff, you benefit from more than 30 years of Industrial RFID expertise. Our systems provide complete tool data with extreme reliability for modern processing centers and guarantee secure operation as well as high productivity of your equipment.

RFID data can be used for asset management and predictive maintenance. The tag can store process-related data such as the tool operating time. Targeted regrinding or replacement of individual tools can be carried out as required.Industrial RFID systems from Balluff provide you with the analysis data that is indispensable for exact cost calculations and modern quality and tool management. All relevant tool data, such as numbers, dimensions or service life, are saved reliably. And are always available. By automating tool loading and data transfer, ToolConnect drastically reduces machine tool setup time, empowering operators to focus on production rather than manual tasks. Moreover, ToolConnect ensures accuracy and reliability, ultimately maximizing chip-cutting time and minimizing disruptions.With ZOLLER, you can already securely transfer tool data to your CNC machine(s) no matter the manufacturer: Via RFID chip, post-processor (DNC system, Distributed Numerical Control), or even through higher level manufacturing control systems.

rfid identification system

Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds. Barcodes and laser engraving have for a long time no longer met the identification requirements of cutting tools in CNC machines.

rfid identification

balluff rfid

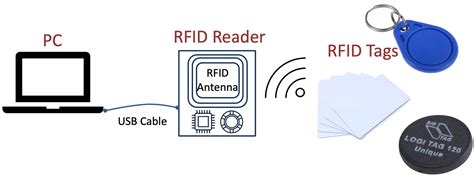

NFC tags and readers communicate wirelessly with each other over very .Host card emulation (HCE) is the software architecture that provides exact virtual representation of various electronic identity (access, transit and banking) cards using only software. Prior to the HCE architecture, near field communication (NFC) transactions were mainly carried out using hardware-based . See more

rfid chips for machine tools|balluff rfid