rfid labels for boeing Off-the-shelf technologies like Bluetooth connectivity and radio-frequency identification (RFID) can be especially helpful in Boeing’s large manufacturing centers, where some teammates work at heights or in confined spaces. UFC Vegas 100 fight card, start time, date and location for the upcoming Neil .

0 · rfid integrated solutions system

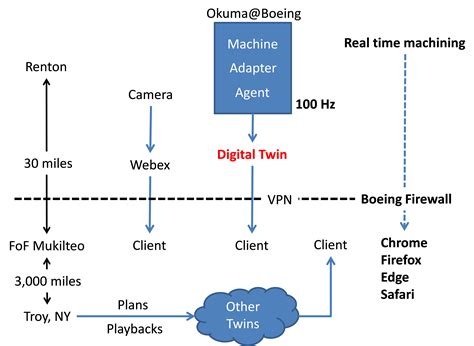

1 · Boeing digital thread

Host-based card emulation. When an NFC card is emulated using host-based card emulation, the data is routed directly to the host CPU instead of being routed to a secure element. Figure 2 illustrates how host-based card .

rfid integrated solutions system

Off-the-shelf technologies like Bluetooth connectivity and radio-frequency identification (RFID) can be especially helpful in Boeing’s large manufacturing centers, where .By providing an easy-to-read view of emergency equipment within an airplane cabin, Boeing’s RFID Integrated Solutions system eliminates the need for technicians to open and close . Off-the-shelf technologies like Bluetooth connectivity and radio-frequency identification (RFID) can be especially helpful in Boeing’s large manufacturing centers, where some teammates work at heights or in confined spaces.By providing an easy-to-read view of emergency equipment within an airplane cabin, Boeing’s RFID Integrated Solutions system eliminates the need for technicians to open and close compartments and use mirrors and flashlights, which adds time and can result in inaccurate data.

Global aerospace company Boeing has deployed a radio frequency identification system for internal manufacturing purposes at four facilities since 2016, using recently released RFID labels from Fujitsu. Earlier this month, Boeing announced it would require many of its suppliers to begin placing RFID tags on a number of parts used in its latest line of commercial airliners, the Dreamliner 787. The airplane manufacturer believes the tags would make it easier for Boeing and its customers to track the parts’ maintenance histories (see Boeing . Boeing uses high-memory RFID tags, ranging in capacity from 8 kilobytes to 4 gigabytes, to store point-of-use life cycle data about a part, component or section of the airplane, including its pedigree and identity, changes in configuration, identity or characteristics (such as hazardous materials or weight), and maintenance history, such as .

Fujitsu Limited today announced that it has signed a contract to supply The Boeing Company with FUJITSU RFID Integrated Labels, as part of a Boeing project to implement RFID technology that improves the efficiency of lifecycle management for aircraft components. Boeing [NYSE: BA] announced plans to introduce radio frequency identification (RFID) "smart labels" on maintenance-significant parts of the 787 Dreamliner. RFID technology will improve configuration control and help airlines reduce costs by managing part maintenance and repair histories. • Meet Boeing D6-84731 type 1 and type 2 RFID tag types as well as BAC5307 • ATA-Spec 2000 compliance • Quickly and accurately print and encode high volumes of RFID tags Boeing and Airbus use RFID tags to make it easier to track, maintain, and replace the thousands of parts that make up airplanes.

Boeing announced plans to introduce radio frequency identification (RFID) "smart labels" on maintenance-significant parts of the 787 Dreamliner. RFID technology will improve. Off-the-shelf technologies like Bluetooth connectivity and radio-frequency identification (RFID) can be especially helpful in Boeing’s large manufacturing centers, where some teammates work at heights or in confined spaces.By providing an easy-to-read view of emergency equipment within an airplane cabin, Boeing’s RFID Integrated Solutions system eliminates the need for technicians to open and close compartments and use mirrors and flashlights, which adds time and can result in inaccurate data.

Global aerospace company Boeing has deployed a radio frequency identification system for internal manufacturing purposes at four facilities since 2016, using recently released RFID labels from Fujitsu. Earlier this month, Boeing announced it would require many of its suppliers to begin placing RFID tags on a number of parts used in its latest line of commercial airliners, the Dreamliner 787. The airplane manufacturer believes the tags would make it easier for Boeing and its customers to track the parts’ maintenance histories (see Boeing .

Boeing uses high-memory RFID tags, ranging in capacity from 8 kilobytes to 4 gigabytes, to store point-of-use life cycle data about a part, component or section of the airplane, including its pedigree and identity, changes in configuration, identity or characteristics (such as hazardous materials or weight), and maintenance history, such as .

Fujitsu Limited today announced that it has signed a contract to supply The Boeing Company with FUJITSU RFID Integrated Labels, as part of a Boeing project to implement RFID technology that improves the efficiency of lifecycle management for aircraft components.

Boeing [NYSE: BA] announced plans to introduce radio frequency identification (RFID) "smart labels" on maintenance-significant parts of the 787 Dreamliner. RFID technology will improve configuration control and help airlines reduce costs by managing part maintenance and repair histories.

• Meet Boeing D6-84731 type 1 and type 2 RFID tag types as well as BAC5307 • ATA-Spec 2000 compliance • Quickly and accurately print and encode high volumes of RFID tags Boeing and Airbus use RFID tags to make it easier to track, maintain, and replace the thousands of parts that make up airplanes.

Boeing digital thread

windows smart card architecture

In corporate environments, NFC Card Emulators can replace physical access cards. Employees can simply tap their smartphones against NFC-enabled card readers to gain .

rfid labels for boeing|rfid integrated solutions system