rfid based ets systems for readymade garments factory Techzen’s RFID solutions can be implemented right from the fabric warehouse to cutting to . To transfer your money faster than one to two business days, you have several .ACM1323S RS232 Contactless Reader Writer. ACM1323 is a smart card reader module based .

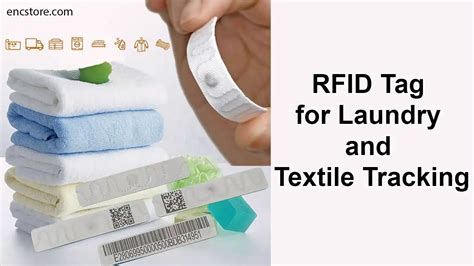

0 · textile rfid tracking

1 · textile rfid tags

2 · textile rfid labels

3 · rfid tracking system

4 · rfid tracking software

Throughout the season, SiriusXM listeners get access to dozens of game broadcasts each week involving teams from the SEC, Big Ten, Big 12, ACC, Pac-12, Big East, and more. October 31, 2024. Get closer to your .

Explore how RFID solutions optimize the garment industry, enhancing efficiency from factory . RFID technology can be used to track each and every item being produced in a .Techzen’s RFID solutions can be implemented right from the fabric warehouse to cutting to .

Explore how RFID solutions optimize the garment industry, enhancing efficiency from factory production to end consumer experience.

RFID technology can be used to track each and every item being produced in a garment factory. Right from the unloading of clothing rolls/bundles to readymade clothing consignments leaving the warehouse, RFID can streamline the entire operation. Here’s a step by step details of RFID technology tracking real-time garment production: 1. RFID .Techzen’s RFID solutions can be implemented right from the fabric warehouse to cutting to sewing to finishing and even on the stations of quality checkers. The company is set to begin its Indian operations that will be guided by the company’s competence of .

Maximize profitability through RFID-based IOT technology, optimizing data entries, and enabling data-driven decisions for enhanced operational efficiency and financial gains. • Real-Time Production Data. • Wages And Incentives System. • Worker And Line-wise Efficiency. • .

I have listed five key benefits of using a real-time production tracking system by a readymade garment factory. These will help you understand why a real-time tech solution essential tool is for managing a factory. For real-time shop floor production tracking and production monitoring in apparel manufacturing, RFID technology is one of the commonly used systems. In this post, I have shared a production tracking system used in a garment factory for real-time production monitoring. RFID stands for Radio Frequency Identification.RFID (Radio Frequency Identification) in the textile industry operates by embedding small RFID tags into textile products or attaching them to the labels. These tags contain unique identification information that can be wirelessly scanned by RFID readers.

RFID technology has revolutionized the apparel industry's factory production process by providing a streamlined and efficient system for tracking inventory and monitoring the production. A real-time production tracking system has the capability to capture bundle start time (with timestamp) and bundle end time at each operation for each bundle and units. ( I am talking about the system for readymade garment manufacturing). In the field of textile and clothing, radio frequency identification (RFID), which is one of the most promising technological innovations, is used in manufacturing, inventory control, warehousing, distribution, logistics, automatic object tracking and supply chain management.

Explore how RFID solutions optimize the garment industry, enhancing efficiency from factory production to end consumer experience. RFID technology can be used to track each and every item being produced in a garment factory. Right from the unloading of clothing rolls/bundles to readymade clothing consignments leaving the warehouse, RFID can streamline the entire operation. Here’s a step by step details of RFID technology tracking real-time garment production: 1. RFID .Techzen’s RFID solutions can be implemented right from the fabric warehouse to cutting to sewing to finishing and even on the stations of quality checkers. The company is set to begin its Indian operations that will be guided by the company’s competence of .

Maximize profitability through RFID-based IOT technology, optimizing data entries, and enabling data-driven decisions for enhanced operational efficiency and financial gains. • Real-Time Production Data. • Wages And Incentives System. • Worker And Line-wise Efficiency. • . I have listed five key benefits of using a real-time production tracking system by a readymade garment factory. These will help you understand why a real-time tech solution essential tool is for managing a factory.

For real-time shop floor production tracking and production monitoring in apparel manufacturing, RFID technology is one of the commonly used systems. In this post, I have shared a production tracking system used in a garment factory for real-time production monitoring. RFID stands for Radio Frequency Identification.RFID (Radio Frequency Identification) in the textile industry operates by embedding small RFID tags into textile products or attaching them to the labels. These tags contain unique identification information that can be wirelessly scanned by RFID readers. RFID technology has revolutionized the apparel industry's factory production process by providing a streamlined and efficient system for tracking inventory and monitoring the production. A real-time production tracking system has the capability to capture bundle start time (with timestamp) and bundle end time at each operation for each bundle and units. ( I am talking about the system for readymade garment manufacturing).

textile rfid tracking

textile rfid tags

textile rfid labels

Umm no. IPhones only read 13.56MHz tags and of those types, only specific ones. No phone, Android or iPhone, can read LF tags. I found a list of apps for iphone when I googled "How To Read NFC Tags With An iPhone". There are .Yes, there are potential security concerns with using a smartphone to transmit/receive 125KHz data. This is because NFC technology is susceptible to hacking and data interception. It is important to take necessary precautions to ensure the safety of sensitive data .

rfid based ets systems for readymade garments factory|textile rfid labels