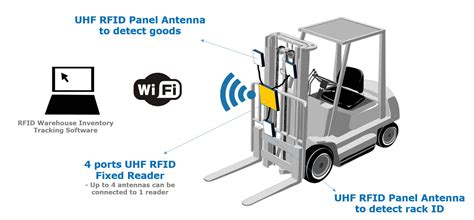

real time rfid inventory tracking RFID inventory tracking effectively monitors items in real-time by labeling each item with an electronic chip. It uses wireless communication to transmit data from tag to reader and helps track items from production to point-of-sale. Sunday, January 23, 2000AFC: Tennessee Titans 33, Jacksonville Jaguars 14The See more

0 · rfid warehouse tracking system

1 · rfid labels for inventory tracking

2 · rfid inventory tracking software

3 · rfid inventory tracker

4 · rfid for warehouse inventory

5 · rfid based inventory tracking system

6 · rfid based asset tracking system

7 · rfid asset tracking software download

You can try NFC Tools or the MiFare Classic Tool to emulate cards from your phone, but in my .

rfid warehouse tracking system

Real-time Inventory Tracking: Monitor your inventory 24/7 and make data-driven .

rfid labels for inventory tracking

RFID inventory tracking effectively monitors items in real-time by labeling each . Real-time Inventory Tracking: Monitor your inventory 24/7 and make data-driven decisions on the fly. Boosted Efficiency and Productivity: Streamline and automate manual processes, allowing your team to focus on more strategic tasks.

RFID inventory tracking effectively monitors items in real-time by labeling each item with an electronic chip. It uses wireless communication to transmit data from tag to reader and helps track items from production to point-of-sale. Tracking inventory levels in real time An RFID system instantly updates product databases, letting your team track inventory in real time. You don’t have to wait for daily or weekly inventory reports. • Real-Time Visibility: Track inventory movement in real-time, allowing you to identify low stock levels and react quickly to prevent stockouts. • Reduced Shrinkage: RFID technology can help deter theft and shrinkage by providing better tracking of high-value items. • Streamlined Operations: Automated inventory management with RFID .

Streamline your warehouse operations with real-time inventory visibility using the latest tracking technologies including RFID, BLE or UWB.

RFID asset tracking offers a benefit in providing insight into inventory levels which allows businesses to quickly and wisely manage stock replenishment and fulfill orders while forecasting demand effectively. RFID and RTLS technologies significantly enhance inventory management through real-time tracking and improved inventory data accuracy, with RFID offering automated data capture and RTLS ensuring precise location tracking.

rfid inventory tracking software

rfid inventory tracker

apc smart-ups 1500va lcd rm 2u 230v with network card

Thanks to real-time inventory tracking, it’s now possible to monitor inventory levels minute-by-minute, giving you an accurate picture of what you have in stock and what you need to reorder. For most of retail history, inventory tracking meant manual data entry in paper ledgers.

RFID is a wireless technology that allows objects to be identified and tracked using radio waves. By leveraging RFID technology, retailers can track inventory in real-time, making it easier to manage, count, and identify inventory while detecting shrinkage.

Real-time tracking of products with RFID technology enhances inventory accuracy by up to 27%. RFID systems significantly speed up processing times by reading multiple tags simultaneously. Implementing RFID can reduce labor costs by up to 30% and improve inventory accuracy rates to 99%. Real-time Inventory Tracking: Monitor your inventory 24/7 and make data-driven decisions on the fly. Boosted Efficiency and Productivity: Streamline and automate manual processes, allowing your team to focus on more strategic tasks.

RFID inventory tracking effectively monitors items in real-time by labeling each item with an electronic chip. It uses wireless communication to transmit data from tag to reader and helps track items from production to point-of-sale. Tracking inventory levels in real time An RFID system instantly updates product databases, letting your team track inventory in real time. You don’t have to wait for daily or weekly inventory reports.

• Real-Time Visibility: Track inventory movement in real-time, allowing you to identify low stock levels and react quickly to prevent stockouts. • Reduced Shrinkage: RFID technology can help deter theft and shrinkage by providing better tracking of high-value items. • Streamlined Operations: Automated inventory management with RFID .Streamline your warehouse operations with real-time inventory visibility using the latest tracking technologies including RFID, BLE or UWB. RFID asset tracking offers a benefit in providing insight into inventory levels which allows businesses to quickly and wisely manage stock replenishment and fulfill orders while forecasting demand effectively.

RFID and RTLS technologies significantly enhance inventory management through real-time tracking and improved inventory data accuracy, with RFID offering automated data capture and RTLS ensuring precise location tracking. Thanks to real-time inventory tracking, it’s now possible to monitor inventory levels minute-by-minute, giving you an accurate picture of what you have in stock and what you need to reorder. For most of retail history, inventory tracking meant manual data entry in paper ledgers. RFID is a wireless technology that allows objects to be identified and tracked using radio waves. By leveraging RFID technology, retailers can track inventory in real-time, making it easier to manage, count, and identify inventory while detecting shrinkage.

rfid for warehouse inventory

rfid based inventory tracking system

Sunday, January 8, 2012. 2011 NFC Wild Card Game; Sun 1/8 1 2 3 4 FINAL; Atlanta (10-6): 0: Pass

real time rfid inventory tracking|rfid labels for inventory tracking