rfid traceability system Traceable supply chain empowers businesses to identify and address issues promptly, ensuring product safety, optimizing operations, and fostering consumer trust. This blog post effectively highlights the importance of RFID in supply . Tap the Read tab to read an NFC tag. Tap the Write tab to write a command for the NFC tag to convey. Tap the Other tab to alter how an NFC tag works. Tap the Tasks tab to .Those readers are incapable of this. Google on collision detection. The nfc 532 adafruit shield will do two. Eg place 3 tags on receiver, the receiver will pick the two strongest .

0 · what is rfid technology

1 · sciencedirect rfid

2 · rfid technology in supply chain

3 · rfid technology in manufacturing

4 · rfid technology in healthcare

5 · rfid enabled technologies

6 · rfid and inventory management

7 · rfid and decision support

I'm a relatively new Gear S3 user, having just received one from my wife for .

what is rfid technology

Traceable supply chain empowers businesses to identify and address issues promptly, ensuring product safety, optimizing operations, and fostering consumer trust. This blog post effectively highlights the importance of RFID in supply .Paragon's RFID solutions are particularly adapted to traceability applications such as tracking the origin of a product, its location, or its journey through the supply chain.Traceable supply chain empowers businesses to identify and address issues promptly, ensuring product safety, optimizing operations, and fostering consumer trust. This blog post effectively highlights the importance of RFID in supply chain traceability.

RFID is an ideal technology to source big data, particularly in supply chains, because RFID tags are consumed across supply chain process, which includes scanning raw materials, completing products, transporting goods, and .

sciencedirect rfid

rfid technology in supply chain

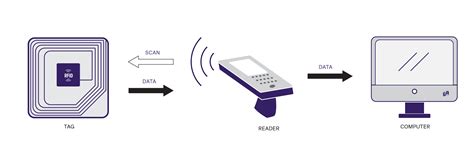

Integrating traditional agricultural product traceability systems with RFID and blockchain technologies offers a transformative enhancement in transparency and data integrity.In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing information throughout the life-cycle of the RFID-tagged assets or products. Essentially, RFID uses radio frequency waves to transfer data wirelessly between a scanner and a tag. In contrast to barcode technology, which requires a stationary scanner, RFID tags can be pinged from anywhere in the world, allowing companies to track real-time movement through the supply chain.

Traceability systems can use GS1-approved barcode symbologies and EPC/RFID tags to encode GS1 identification keys that uniquely identify products, trade items, logistic units, locations, assets, and service relations worldwide.

Radio frequency identification (RFID) is a contactless technology for the automatic identification of objects, animals, and people associated with a transponder (tag). This auto identification technology can be utilized for traceability systems in . Traceability systems make it possible to trace the origin of counterfeit products and put a halt to their production. Traceability also allows unsafe products to be tracked and recalled, enabling important consumer protections (Uddin, 2021). The purpose of this paper is to develop an efficient tool to ensure traceability data entry based on RFID and improve the detection of fakes inside the supply chain.

Paragon's RFID solutions are particularly adapted to traceability applications such as tracking the origin of a product, its location, or its journey through the supply chain.Traceable supply chain empowers businesses to identify and address issues promptly, ensuring product safety, optimizing operations, and fostering consumer trust. This blog post effectively highlights the importance of RFID in supply chain traceability.

hid card vs rfid

RFID is an ideal technology to source big data, particularly in supply chains, because RFID tags are consumed across supply chain process, which includes scanning raw materials, completing products, transporting goods, and .

Integrating traditional agricultural product traceability systems with RFID and blockchain technologies offers a transformative enhancement in transparency and data integrity.In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing information throughout the life-cycle of the RFID-tagged assets or products. Essentially, RFID uses radio frequency waves to transfer data wirelessly between a scanner and a tag. In contrast to barcode technology, which requires a stationary scanner, RFID tags can be pinged from anywhere in the world, allowing companies to track real-time movement through the supply chain.Traceability systems can use GS1-approved barcode symbologies and EPC/RFID tags to encode GS1 identification keys that uniquely identify products, trade items, logistic units, locations, assets, and service relations worldwide.

Radio frequency identification (RFID) is a contactless technology for the automatic identification of objects, animals, and people associated with a transponder (tag). This auto identification technology can be utilized for traceability systems in . Traceability systems make it possible to trace the origin of counterfeit products and put a halt to their production. Traceability also allows unsafe products to be tracked and recalled, enabling important consumer protections (Uddin, 2021).

rfid technology in manufacturing

$29.99Nintendo NFC Reader and Writer Accessory for Nintendo 3DS, 3DS XL and .

rfid traceability system|rfid and inventory management