rfid pallet tracking with sap In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing . Amiibo cards are ridiculously easy and cheap to mass-produce, to the point that anyone with a .

0 · rfid tracking devices

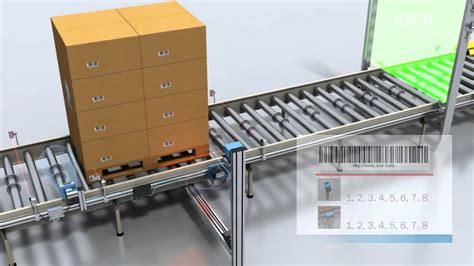

1 · rfid scan station for pallet

2 · rfid pallet tracking system

3 · rfid asset tracking system

4 · rf tracking system

5 · rf tracking device

6 · pallet identification tags

7 · barcode tracking system

This library provides an easy way to interface with the RC522 module. Open the Arduino IDE. Go to Sketch > Include Library > Manage Libraries. Search for "MFRC522" and install the library by GithubCommunity. .

RFID in SAP Extended Warehouse Management. Technical Details of SAP EWM RFID. What is RFID and for what is it used? Radio Frequency Identification is a technology to .RFID in SAP EWM enables contact-free identification, control, and tracking of packaged pro. This blog post outlines the required steps to maintain traceability across the supply chains using Barcode & RFIDs in combination with SAP offerings. Overview. This particular guide focuses on picking with RF. When using radio frequency (RF) devices to carry out warehouse activities, you can scan bar codes to record and verify data .

In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing .We helped a major utilities company track the movement of their pallets by integrating RFID scanning into SAP - without bothering IT, without touching the ba. Benefits of RFID in SAP EWM. Increased Accuracy: RFID reduces errors associated with manual data entry and barcode scanning, significantly increasing inventory . This article provides an overview of the integration of RFID technology with S/4HANA EWM (Extended Warehouse Management). We will explore the typical requirements .

RFID in EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, RFID .RFID in SAP EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, .RFID enables real-time product tracking within the SAP WM system, allowing warehouse managers to identify and address any issues related to product tracking quickly. RFID's ability . RFID in SAP Extended Warehouse Management. Technical Details of SAP EWM RFID. What is RFID and for what is it used? Radio Frequency Identification is a technology to identify and track tags attached to objects through electromagnetic waves [1]. That said, while RFID is a technology, it is not a standard by itself.

This blog post outlines the required steps to maintain traceability across the supply chains using Barcode & RFIDs in combination with SAP offerings. Overview. This particular guide focuses on picking with RF. When using radio frequency (RF) devices to carry out warehouse activities, you can scan bar codes to record and verify data such as storage bins, products, and handling unit (HU) numbers, or you can enter picked quantities.

In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing information throughout the life-cycle of the RFID-tagged assets or products.We helped a major utilities company track the movement of their pallets by integrating RFID scanning into SAP - without bothering IT, without touching the ba. Benefits of RFID in SAP EWM. Increased Accuracy: RFID reduces errors associated with manual data entry and barcode scanning, significantly increasing inventory accuracy. Real-time Inventory. This article provides an overview of the integration of RFID technology with S/4HANA EWM (Extended Warehouse Management). We will explore the typical requirements or business benefits, the architecture of RFID, its standard support and processes, and also discuss some of the equipment involved.

RFID in EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, RFID tags offer the following advantages:RFID in SAP EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, RFID tags offer the following advantages:RFID enables real-time product tracking within the SAP WM system, allowing warehouse managers to identify and address any issues related to product tracking quickly. RFID's ability to scan and track items without line-of-sight makes it especially valuable for densely packed warehouses with items in various orientations.

RFID in SAP Extended Warehouse Management. Technical Details of SAP EWM RFID. What is RFID and for what is it used? Radio Frequency Identification is a technology to identify and track tags attached to objects through electromagnetic waves [1]. That said, while RFID is a technology, it is not a standard by itself. This blog post outlines the required steps to maintain traceability across the supply chains using Barcode & RFIDs in combination with SAP offerings. Overview. This particular guide focuses on picking with RF. When using radio frequency (RF) devices to carry out warehouse activities, you can scan bar codes to record and verify data such as storage bins, products, and handling unit (HU) numbers, or you can enter picked quantities.

In order to realize the true potential of RFID, it is indispensable for organizations to enable business processes across the value chain and provide end-to-end traceability by capturing information throughout the life-cycle of the RFID-tagged assets or products.We helped a major utilities company track the movement of their pallets by integrating RFID scanning into SAP - without bothering IT, without touching the ba. Benefits of RFID in SAP EWM. Increased Accuracy: RFID reduces errors associated with manual data entry and barcode scanning, significantly increasing inventory accuracy. Real-time Inventory. This article provides an overview of the integration of RFID technology with S/4HANA EWM (Extended Warehouse Management). We will explore the typical requirements or business benefits, the architecture of RFID, its standard support and processes, and also discuss some of the equipment involved.

rfid business card filetype:html

RFID in EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, RFID tags offer the following advantages:RFID in SAP EWM enables contact-free identification, control, and tracking of packaged products and handling units by using RFID labels with integrated RFID tags. In contrast to barcodes, RFID tags offer the following advantages:

rfid tracking devices

rfid scan station for pallet

rfid pallet tracking system

The problems seems to be that it's not possible to emulate/modify the sector 0, which is often the UID (identifier). This question is linked (but probably outdated). It is possible .

rfid pallet tracking with sap|barcode tracking system