rfid technology applied in warehouse management system The WMS based on RFID will help to improve the efficiency of warehouse . I thought I would share some helpful tips that I think most don’t know about .

0 · using rfid to track inventory

1 · rfid warehouse tracking system

2 · rfid warehouse management system requirements

3 · rfid warehouse inventory management

4 · rfid tracking systems for inventory

5 · rfid in warehouse management pdf

6 · rfid disadvantages

7 · pros and cons of rfid

Step 2: Tap New Automation or + (from the top-right corner). Step 3: Here, scroll down or search for NFC. Tap it. Step 4: Tap Scan. Hold your device over an NFC tag/sticker. Step 5: Name the tag .

The WMS based on RFID will help to improve the efficiency of warehouse .The WMS based on RFID will help to improve the efficiency of warehouse .This question is for testing whether you are a human visitor and to prevent .This question is for testing whether you are a human visitor and to prevent .

Making use of advanced RFID technology, the paper proposes a comprehensive . The WMS based on RFID will help to improve the efficiency of warehouse management, and make rapid self-recording of receiving and delivery.

Making use of advanced RFID technology, the paper proposes a comprehensive and functional solution for sight spots in areas of design of electronic tickets, RFID data integration, hardware .One of the most impactful types of technology employed in modern warehouses and distribution centers is radio frequency identification (RFID) sensor systems. This guide will discuss RFID use in a warehouse and how it makes a difference.

using rfid to track inventory

The current research on RFID (radio frequency identification) technology related to warehouse management system is expounded and the main differences between traditional and RFID-based warehousing business process are proposed. 1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey. This decreases the risk of stockouts, overstocking, and the associated costs. The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods.

By incorporating RFID technology with a warehouse management system, you will reduce your storage handling costs, improve accuracy and maximize the rate at which things get done. In the end, RIFD makes for more efficient storage and more satisfied customers.

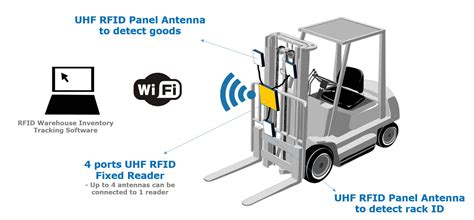

warehouse management to support all processes of the supply chain. As a modern data-collection tool, RFID will be applied widely in the warehouse management system with its remarkable.An RFID warehouse management system is a system that utilizes radio frequency identification technology to track and manage items within a warehouse. By employing RFID tags and readers, companies can monitor inventory status in real-time and automatically record the entry, exit, and storage locations of items, thereby enhancing the efficiency . Initially created for general object tracking, RFID has become a game-changer in inventory and warehouse management. It’s a step up from traditional barcodes, offering real-time data on stock levels and locations. This technology makes inventory processes smoother, cuts down on manual work, and improves accuracy. How RFID works. The WMS based on RFID will help to improve the efficiency of warehouse management, and make rapid self-recording of receiving and delivery.

Making use of advanced RFID technology, the paper proposes a comprehensive and functional solution for sight spots in areas of design of electronic tickets, RFID data integration, hardware .One of the most impactful types of technology employed in modern warehouses and distribution centers is radio frequency identification (RFID) sensor systems. This guide will discuss RFID use in a warehouse and how it makes a difference. The current research on RFID (radio frequency identification) technology related to warehouse management system is expounded and the main differences between traditional and RFID-based warehousing business process are proposed.

1. Improved Inventory Management and Accuracy. An RFID system enables real-time inventory tracking, so companies can quickly and accurately locate items in their warehouses or throughout the supply chain journey. This decreases the risk of stockouts, overstocking, and the associated costs. The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods. By incorporating RFID technology with a warehouse management system, you will reduce your storage handling costs, improve accuracy and maximize the rate at which things get done. In the end, RIFD makes for more efficient storage and more satisfied customers.

warehouse management to support all processes of the supply chain. As a modern data-collection tool, RFID will be applied widely in the warehouse management system with its remarkable.

An RFID warehouse management system is a system that utilizes radio frequency identification technology to track and manage items within a warehouse. By employing RFID tags and readers, companies can monitor inventory status in real-time and automatically record the entry, exit, and storage locations of items, thereby enhancing the efficiency .

rfid warehouse tracking system

does my debit card have rfid

rfid warehouse management system requirements

If I scan the tag in NFC Tools or in Shortcuts it scans perfectly without any problems, but if I try to scan it normally, there is no response. . I’ve simply tested trying to read it through Shortcuts .

rfid technology applied in warehouse management system|rfid warehouse management system requirements